91746150

VAG MULTILINK TOP SUSPENSION BOLT DRILL OUT KIT

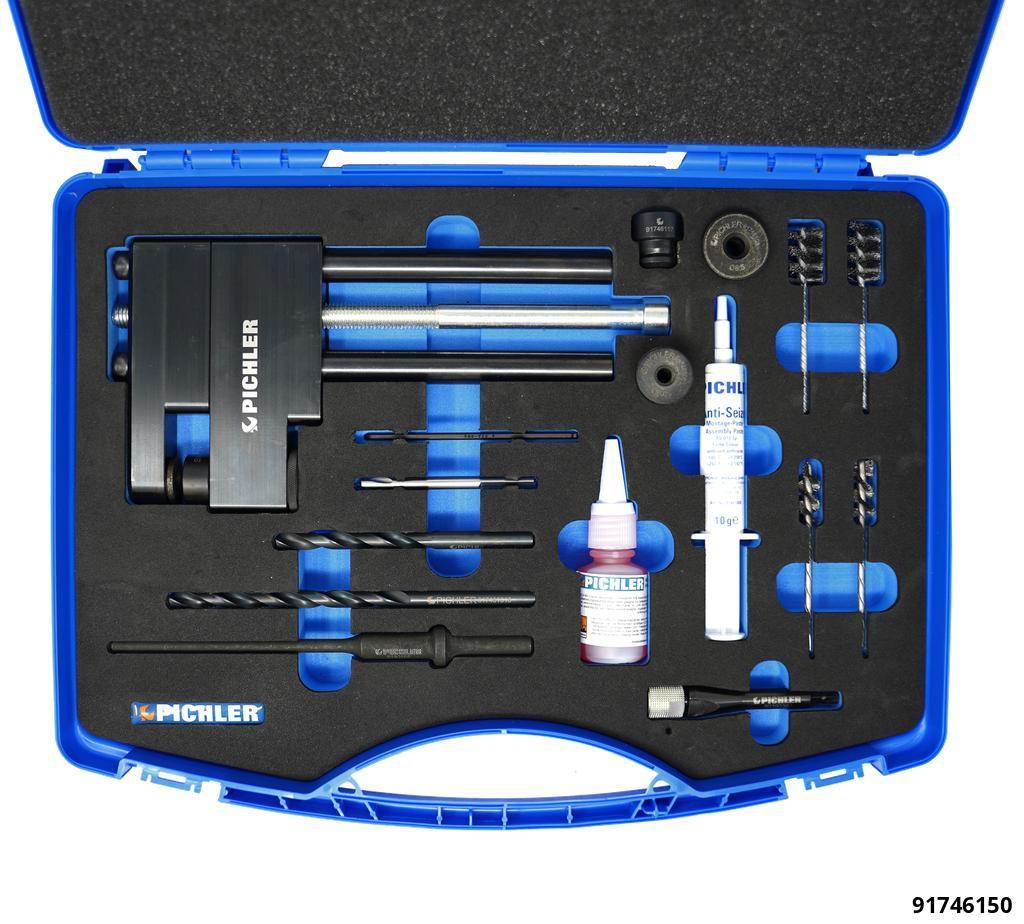

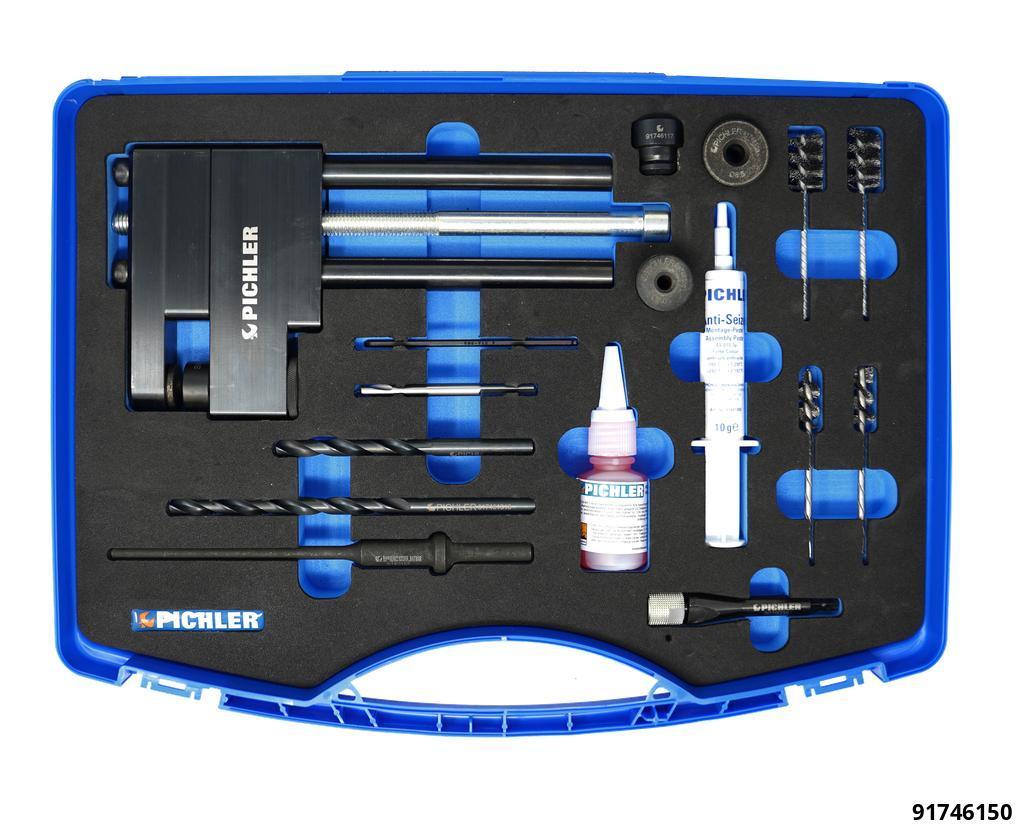

Specifically developed for precision drilling of the top suspension bolt on aluminium and steel steering knuckles found across VAG Group vehicles, this kit provides a reliable solution for one of the most problematic and labour-intensive tasks in suspension servicing.

Over time, the upper suspension bolt becomes heavily corroded due to its exposed position—subjected to water ingress, road salt, and environmental grime. This makes traditional removal methods such as twisting or hammering not only ineffective, but potentially damaging, often resulting in broken steering knuckle clamps or severely deformed bolts.

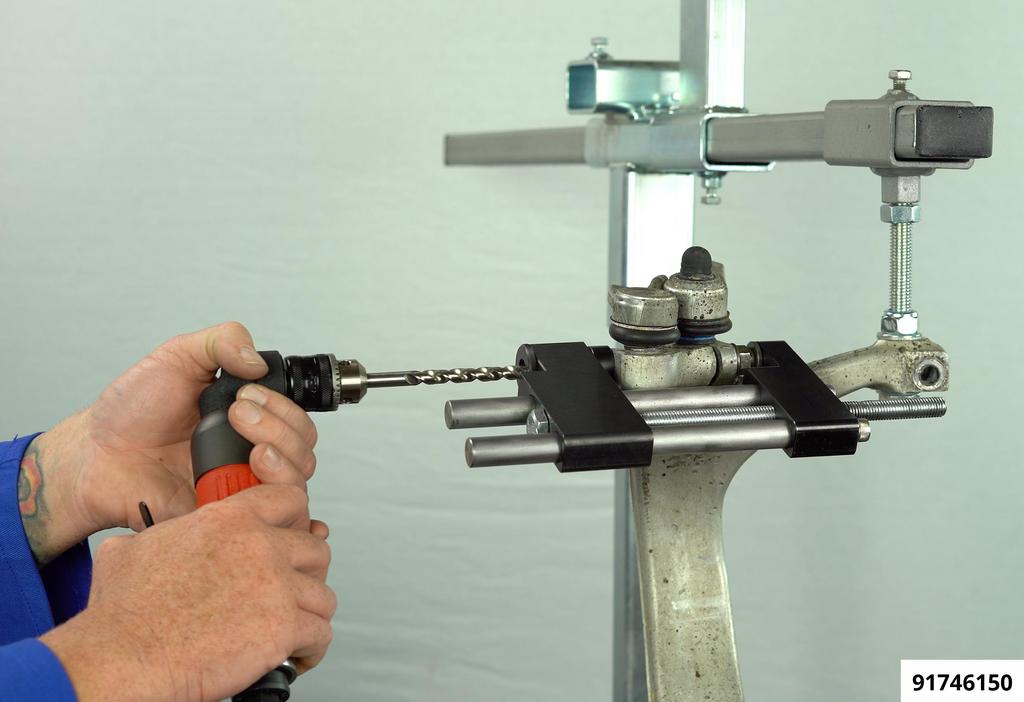

The jig clamps securely around the steering knuckle while the suspension remains on the vehicle. It guides the drill precisely to the centre of the corroded bolt, enabling accurate and safe material removal without misalignment.

Key Benefits:

Designed for use on both aluminium and steel VAG steering knuckles

Eliminates risk of snapping clamps or damaging adjacent components

Secure on-vehicle clamping ensures stable and centralised drilling

Adjustable jig accommodates various knuckle geometries

Saves time, reduces technician effort, and minimises costly component replacement

Procedure:

Clamp the adjustable jig around the steering knuckle

Drill a precise centring hole through the corroded bolt

Drill out the bolt core using guided alignment

Use a vibration gun to release and remove remaining bolt segments

Clean out the bore using included cleaning bushes to remove corrosion and debris

Fit new bolt into the restored clamping point

002

Over time, the upper suspension bolt becomes heavily corroded due to its exposed position—subjected to water ingress, road salt, and environmental grime. This makes traditional removal methods such as twisting or hammering not only ineffective, but potentially damaging, often resulting in broken steering knuckle clamps or severely deformed bolts.

The jig clamps securely around the steering knuckle while the suspension remains on the vehicle. It guides the drill precisely to the centre of the corroded bolt, enabling accurate and safe material removal without misalignment.

Key Benefits:

Designed for use on both aluminium and steel VAG steering knuckles

Eliminates risk of snapping clamps or damaging adjacent components

Secure on-vehicle clamping ensures stable and centralised drilling

Adjustable jig accommodates various knuckle geometries

Saves time, reduces technician effort, and minimises costly component replacement

Procedure:

Clamp the adjustable jig around the steering knuckle

Drill a precise centring hole through the corroded bolt

Drill out the bolt core using guided alignment

Use a vibration gun to release and remove remaining bolt segments

Clean out the bore using included cleaning bushes to remove corrosion and debris

Fit new bolt into the restored clamping point

002

Order here now

If you require any further information please call 01335 360759